Factors of Production

by msypniewski511 in Business and Entrepreneurship

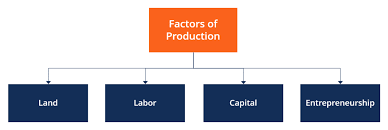

Factors of Production

The factors of production refer to the resources or inputs used to create goods and services. They are the building blocks of any economy, and understanding them is key to grasping how businesses and economies function. There are four main factors of production:

1. Land:

- Definition: Refers to all natural resources that are used to produce goods and services. This includes not only the land itself but also resources like minerals, forests, water, and energy sources.

- Examples: Farmland, oil deposits, forests, rivers, and other natural resources.

- Economic Return: Rent is the income earned from the use of land or natural resources.

2. Labor:

- Definition: Refers to human effort, both physical and mental, that is used in the production process. This includes workers of all types, from factory laborers to professionals like engineers or doctors.

- Examples: Factory workers, teachers, engineers, construction workers, and service providers.

- Economic Return: Wages or salaries are paid in exchange for labor.

3. Capital:

- Definition: Refers to man-made tools, machines, buildings, and other equipment that are used in the production of goods and services. Capital can be physical or financial.

- Examples: Machinery, factories, computers, vehicles, and investment capital used to purchase equipment.

- Economic Return: Interest or profit is the income earned from the use of capital.

- Types of Capital:

- Physical Capital: Machinery, tools, factories, and infrastructure.

- Financial Capital: Money or financial assets used to invest in businesses or purchase physical capital.

4. Entrepreneurship:

- Definition: Refers to the ability to combine the other factors of production (land, labor, and capital) to produce goods and services. Entrepreneurs take risks to start new businesses, innovate, and create value.

- Examples: Business owners, startup founders, inventors, and innovators.

- Economic Return: Profit is the reward for entrepreneurship, which comes from successfully organizing production and taking on risk.

Importance of the Factors of Production:

Interdependence: These factors must work together to produce goods and services. For example, labor is needed to work on the land, and capital (machinery, investment) is needed to make labor more efficient.

Economic Growth: An increase in the quantity or quality of these factors can lead to higher productivity and, in turn, economic growth.

Scarcity and Allocation: Each of these resources is limited, and economics often deals with how to best allocate them to meet the needs of society.

Technological Impact: Advancements in technology can significantly affect the productivity of these factors, especially labor and capital, by making production processes more efficient.

Other Considerations:

Technology: Although not traditionally considered a factor of production, technology is critical in modern production processes. It can enhance the productivity of land, labor, and capital, leading to greater efficiency and output.

Knowledge and Human Capital: Sometimes, human capital (the skills, education, and expertise of the workforce) is treated as a separate factor of production because it plays such a crucial role in modern economies.

Summary of Economic Returns:

- Land → Rent

- Labor → Wages

- Capital → Interest

- Entrepreneurship → Profit

Together, these factors of production drive economic activity by contributing to the creation of goods and services that satisfy consumer needs and wants. Efficient use of these factors can lead to increased productivity, economic growth, and improved standards of living.

Relationship among the Factors of Production

The factors of production---land, labor, capital, and entrepreneurship---are interdependent and work together in a coordinated way to produce goods and services. Each factor plays a unique role, but none can function effectively in isolation. Here's a breakdown of the relationship among the factors of production:

1. Land and Labor:

- Land provides the natural resources, while labor refers to the human effort that transforms these resources into goods and services.

- For example, agricultural production depends on both the availability of fertile land and the labor of farmers to plant, grow, and harvest crops.

- In industries like mining, labor is needed to extract resources (like minerals or oil) from the land, showing the clear interdependence between these two factors.

2. Land and Capital:

- Capital (machinery, tools, buildings) enhances the productivity of land by enabling more efficient extraction, processing, and utilization of natural resources.

- For example, in farming, the use of tractors (capital) makes the cultivation of land more efficient. In mining, advanced machinery allows for more effective extraction of resources from the earth.

- Capital investments can also improve the quality of land over time (e.g., irrigation systems or fertilizers).

3. Labor and Capital:

- Labor and capital work together to improve productivity. Human labor operates capital (machinery, tools, etc.) to increase efficiency and output.

- In manufacturing, for example, laborers operate machines that assemble products at a much faster rate than manual labor alone could achieve.

- Skilled labor is often required to effectively use more complex capital (e.g., computer programming, operating machinery), illustrating how labor and capital complement each other.

4. Entrepreneurship and the Other Factors:

- Entrepreneurship is the factor that brings together land, labor, and capital to create value. Entrepreneurs organize these resources to start businesses, innovate, and generate goods or services.

- Entrepreneurs identify opportunities, make decisions about how to allocate resources, and take risks by investing capital and hiring labor to utilize land and produce goods.

- For example, in the tech industry, an entrepreneur may recognize a demand for a new app, hire skilled labor (software developers), acquire capital (computers, servers), and use online platforms (land in the digital sense) to launch the product.

5. Capital and Entrepreneurship:

- Capital is essential for entrepreneurship to thrive, as entrepreneurs need financial resources to start and grow their ventures. Capital is often used to buy equipment, pay workers, and invest in infrastructure.

- Conversely, entrepreneurship is necessary for the effective deployment of capital. An entrepreneur decides how to invest capital to maximize returns, whether in machinery, research, or hiring skilled workers.

- For example, in a startup, the entrepreneur uses seed funding (capital) to hire engineers (labor) and buy computers (capital) to develop a product, coordinating all factors for production.

6. Land and Entrepreneurship:

- Entrepreneurship identifies and leverages opportunities associated with land, whether it's natural resources, real estate, or even digital space.

- Entrepreneurs in industries such as agriculture, real estate development, or energy use land as a key resource to build businesses. In tech, the "land" might be the digital space where businesses operate online.

Summary of Interdependence:

- Land, labor, and capital are passive factors of production, meaning they require entrepreneurship to be activated and organized.

- Labor increases the productivity of land and capital, while capital makes labor more efficient.

- Entrepreneurs are key to combining all three passive factors (land, labor, and capital) to create value, making entrepreneurship the "active" force behind production.

In essence, the factors of production are like the pieces of a puzzle, each relying on the other to function effectively. Their harmonious interaction is essential for producing goods and services, growing the economy, and creating value.

Production

Production refers to the process of creating goods or services by combining various resources or inputs, such as labor, capital, land and entrepreneurship, to satisfy human needs and wants. It involving transforming raw materials or inputs into finished goods or services that can be consumed by individuals, businesses, or governments.

Key Apsects of Production:

- Transformation of Inputs to Outputs: Production converts raw materials (inputs) into finished goods or services (outputs). For example, turning raw cotton into fabric, or converting steel into cars.

- Value Creation: The goal of production is to add value by enhancing the utility of resources. For example, flour becomes more valuable when it's turned into bread.

- Economic Activity: Production is central to economic activity because it drives supply in markets, provides employment, and is essential for economic growth.

- Types of Production:

- Primary Production: Involves extracting and using natural resources, like agriculture, fishing, or mining.

- Secondary Production: Includes the manufacturing and construction industries, where raw materials are transformed into finished goods.

- Tertiary Production: Focuses on providing services, such as retail, banking, healthcare, and education.

- Production Process:

- Input: Resources like raw materials, labor, capital, and entrepreneurship.

- Process: The methods or techniques used to convert inputs into outputs, such as manufacturing or service delivery.

- Output: The final goods or services produced.

Importance of Production:

- Satisfies Human Needs: The main purpose of production is to meet the demand for goods and services, ensuring the needs and wants of society are fulfilled.

- Economic Growth: The more efficiently production takes place, the more goods and services an economy can provide, leading to increased wealth and a higher standard of living.

- Job Creation: Production processes require labor, leading to employment opportunities and income generation for individuals.

- Wealth Creation: Businesses and economies generate profit through production, which leads to wealth creation for individuals, companies, and countries.

Factors Influencing Production:

- Technology: Advances in technology can make production more efficient by reducing costs, increasing output, or improving quality.

- Availability of Resources: The quantity and quality of inputs like raw materials, labor, and capital affect how much can be produced.

- Cost of Production: The price of inputs (labor, materials, etc.) influences how much it costs to produce goods and services, affecting profit margins.

- Government Policies: Taxes, subsidies, regulations, and trade policies can impact production by influencing the cost and availability of inputs or markets.

- Market Demand: The demand for certain goods and services drives production levels. Businesses produce more when demand is high and reduce output when demand falls.

Types of Production Systems:

- Mass Production: Large-scale production of standardized products, usually with the help of assembly lines and automation (e.g., car manufacturing).

- Batch Production: Producing goods in batches, where a set number of items are produced at once before switching to another type of product (e.g., bakery goods).

- Job Production: Producing custom or specialized products, often one at a time (e.g., building a custom house or designing bespoke furniture).

- Lean Production: A method that focuses on minimizing waste and maximizing efficiency in the production process.

Production process

The production process refers to the series of steps and activities that transform inputs (raw materials, labor, and capital) into finished goods or services. It involves various stages of planning, organizing, and executing to ensure efficient creation of products that meet consumer needs. The production process varies by industry, but the fundamental principles remain the same.

Key Stages in the Production Process:

- Input:

- The first stage of production involves gathering the necessary inputs or resources required for the production process. These inputs include:

- Raw materials: Natural resources (e.g., wood, minerals, oil) or components (e.g., metals, plastic).

- Labor: Human effort, skills, and knowledge.

- Capital: Machinery, tools, factories, and financial resources.

- Entrepreneurship: The decision-making and coordination of resources by entrepreneurs.

- Example: In a car manufacturing plant, inputs include steel (raw material), factory workers (labor), assembly line machines (capital), and the company's strategy (entrepreneurship).

- The first stage of production involves gathering the necessary inputs or resources required for the production process. These inputs include:

- Processing/Transformation:

- During this stage, the raw materials and inputs are processed and transformed into finished or semi-finished products. The transformation is done using labor and machinery, often following a structured process that ensures quality and efficiency.

- The transformation process can take many forms, such as:

- Manufacturing: Converting raw materials into finished products (e.g., steel to cars, fabric to clothing).

- Assembly: Putting together components to make a final product (e.g., assembling computers, furniture).

- Service delivery: For non-physical products, this involves organizing resources to deliver services (e.g., consulting services, medical treatments).

- Example: In car manufacturing, processing involves cutting, welding, assembling parts, painting, and quality testing.

- Output:

- The result of the production process is the output, which refers to the finished goods or services ready for consumption by customers or further use in other production processes.

- Example: The output in a car factory is the fully assembled car ready to be sold to consumers or dealerships.

- Distribution and Logistics:

- Once the product is produced, it needs to be distributed to the final consumer or retailer. This stage involves packaging, transportation, inventory management, and logistics to ensure the product reaches its destination on time.

- Example: Cars are shipped from the factory to dealerships, warehouses, or directly to customers.

- Feedback and Improvement:

- After the product has been distributed, businesses often gather feedback from consumers, employees, or market data to identify areas for improvement in the production process. This feedback can lead to innovations, better quality control, or more efficient operations.

- Example: Customer feedback on car performance might lead the manufacturer to improve engine efficiency or add new features in future models.

Types of Production Processes:

- Job Production:

- Definition: Producing a single, customized product or service to meet a specific client's needs.

- Example: Building a custom house, designing a wedding dress.

- Advantages: High customization and client satisfaction.

- Disadvantages: Higher costs and slower production due to specialization.

- Batch Production:

- Definition: Producing goods in batches, where a group of products goes through the production process together.

- Example: Baking a batch of cookies or producing a batch of T-shirts.

- Advantages: Economies of scale, less idle time for machinery.

- Disadvantages: Delays between batches and less customization than job production.

- Mass Production:

- Definition: Producing large quantities of standardized products, often using assembly lines.

- Example: Manufacturing cars, electronics, or packaged foods.

- Advantages: High efficiency, lower costs per unit, consistent quality.

- Disadvantages: Less flexibility, high upfront costs for machinery and infrastructure.

- Flow/Continuous Production:

- Definition: A highly automated process where production flows continuously without interruption.

- Example: Oil refining, chemical manufacturing, power generation.

- Advantages: Maximum efficiency, reduced costs, consistent output.

- Disadvantages: Extremely high setup costs, lack of flexibility in changing production.

- Lean Production:

- Definition: A method focused on minimizing waste while maximizing productivity and quality.

- Example: Toyota's production system, where resources and processes are streamlined for efficiency.

- Advantages: Reduced waste, lower costs, higher efficiency.

- Disadvantages: Requires a highly skilled workforce and continuous management attention.

Key Elements of an Efficient Production Process:

- Planning:

- Careful planning ensures that all inputs are available when needed and that the production process flows smoothly.

- Quality Control:

- Monitoring the production process to ensure that the final product meets quality standards. This can involve inspections, testing, and adherence to standards.

- Inventory Management:

- Managing raw materials and finished goods inventory is critical to avoid production delays or excess stock, which can increase costs.

- Automation:

- Increasing automation in production processes can improve efficiency and reduce human error, particularly in industries that use repetitive tasks.

- Sustainability:

- Modern production processes also focus on sustainability by reducing waste, energy consumption, and environmental impact. This can improve efficiency and appeal to eco-conscious consumers.

Conclusion:

The production process is a structured and systematic approach to turning inputs into outputs, whether it involves manufacturing goods or delivering services. The efficiency of the production process is critical to profitability, quality, and customer satisfaction. By leveraging different production systems and continuously improving operations, businesses can optimize the use of resources and meet market demands.

0 Replies

Leave a replay

To replay you need to login. Don't have an account? Sign up for one.